Baker Hughes HPump SPS

Surface Pumping Systems - Baker Hughes

Applications

- Borehole mining

- CO2 injection/booster

- CO2 sequestration

- Condensate transfer

- Crude oil boosting/transfer

- Dust suppression

- Geothermal

- Hydraulic power fluid boosting

- Jet pumping

- Lean amine circulation

- Mine dewatering

- NGL boosting/transfer

- Offshore facilities fluid handling

- Pipeline boosting

- Process fluids transfer

- Produced water disposal/injection

- Salt dome leaching

- Seawater disposal/waterflooding

- Wash water circulation

- Water transfer

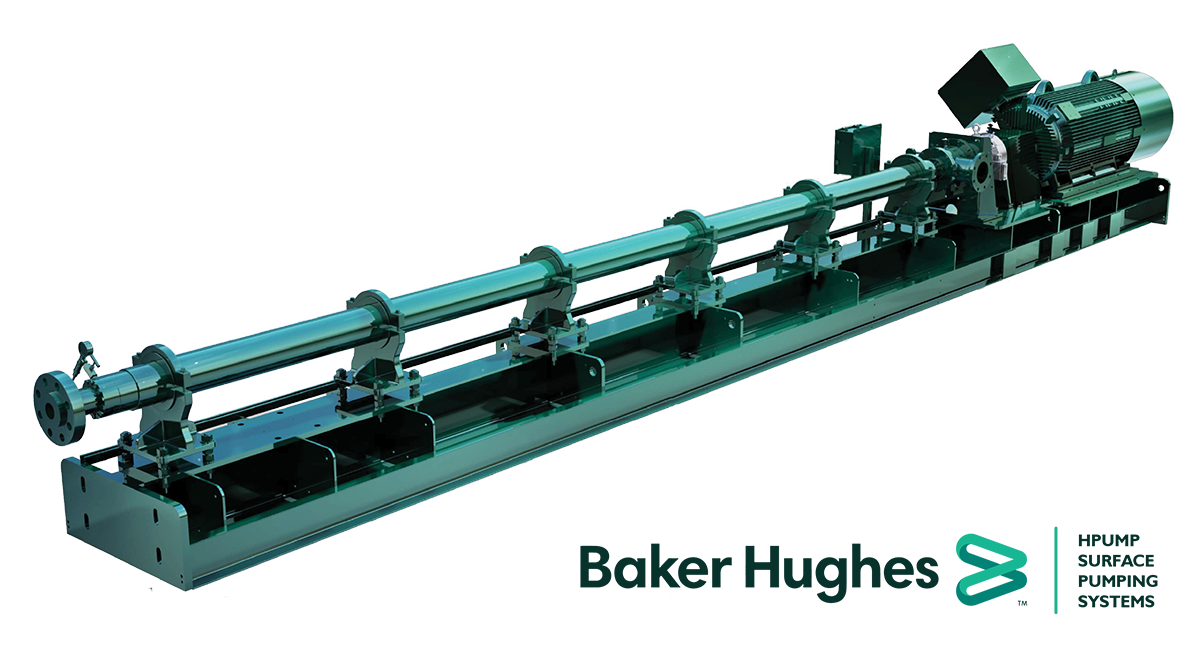

Improved surface pumping solutions

- Long-lasting, highly-reliable, environmentally-friendly pumping solutions

- Baker Hughes' SPS pumping systems provide versatile, low-maintenance alternatives to many high-speed integral geardriven centrifugal (OH6), positive displacement (PD), and vertical-turbine pump (VTP) models

Pre-packaged units

- Baker Hughes' SPS pumps are available in gas, electric or dieselpowered models

- Capability to handle up to 2,500 gpm (85,000 BFPD) and discharge pressures up to 6000 psi

- Delivered to the job site pre-assembled—only requiring suction flange, discharge flange and power hookups

- The Easily Modified SPS Frame (EMF™) is pre-wired with instrumentation and cabling terminated in a central junction box. This proprietary frame, paired with the versatile design of Baker Hughes' pumps, allows for easy on-site installation and maintenance with minimal site preparation

Trouble-free service

- Designed for years of trouble-free operation

- There are no V-belts or packing to service

- Routine maintenance consists of a quarterly lubricant change and component check

- SPS units generate little to no vibration-related wear or stress on piping components and they are available with a variety of mechanical seal options (including API 682 seals)

- The modular design makes SPS units suitable for a wide variety of applications, from routine water injection to mine dewatering and leaching operations

Mine Water Management

- Mine dewatering is usually undertaken to ensure the stability of mine walls during and after excavation, or to optimize mine production and increase operational efficiencies

- In many mines, the amount of water that must be pumped exceeds the mines’ water consumption requirements. In this case, a majority of the excess water is discharged to Baker Hughes' surface SPS water pumping systems, reinjected into aquifers, applied to crop land, or piped to power plants

Cavern Leaching

- There are numerous cavern leaching and/or formation jetting (borehole mining) applications

- In salt dome leaching processes, Baker Hughes' SPS pumps are frequently used to circulate water, absorbing the salt. A large underground cavern is formed after the salt has been leached and the water is removed

- Baker Hughes' SPS pumps are also used to re-inject materials such as oil, natural gas, hydrogen gas, or even hazardous waste into the empty caverns for storage